| |

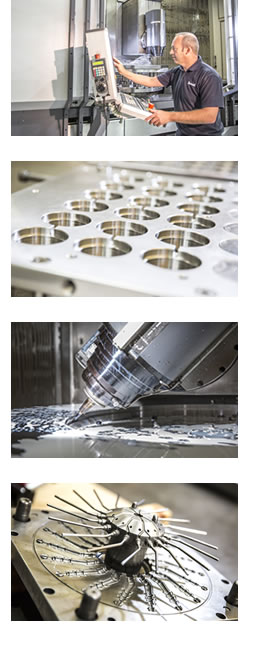

Burnsall Engineering offers a precision engineering service second to none. The company specialises in rubber and plastic mould tools and large scale milling and turning..

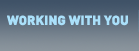

Mould tools

Our core strength lies in rubber mould tool making, providing the services required to see a mould tool project through from initial component, to concept, through design revisions to the final realised product & cold trials

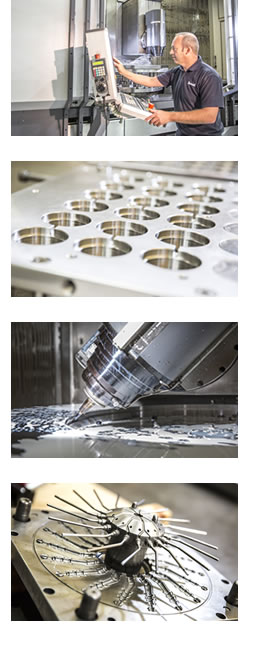

The range of tooling supplied varies from single cavity loose compression rubber moulds up to large multi-cavity injection rubber moulds, with automated features such as ejection, shuttling plates & de-moulding. Other rubber moulding ancillaries such as manifolds (Cold Runner Blocks), heated plattens, ejector plates & load trays are also catered for.

Burnsall Engineering's mould making expertise was originally founded in the sealing sectors, with 'O' Rings & gaskets being a speciality. Over the decades this core market has expanded into all types of mould & tool making in the rubber industry, with regular rubber mould tool projects in the automotive, oil & gas, medical & electrical industries.

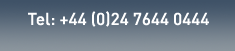

Large-scale milling and turning

Burnsall's continuous investment in plant and machinery has included large-scale milling and turning. Our 5-axis milling centre can deal with up to 1600mm turning and milling of 3000 x 1100mm and 2500 x 1500mm . Our customers are mainly from oil & gas, aerospace, medical and mining industries.

General engineering

As well as rubber mould tooling, other sectors we service include precision machined components for the automotive & auto sport industries, sensitive medical industry components along with regularly supplying highly accurate parts lying within the heart of automated production lines & custom machinery.

|