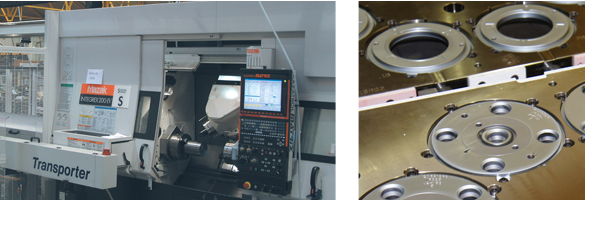

Investment in equipment

In line with our policy of continual re-investment, we are proud to list the capacity of our plant machinery;

3 off 5-Axis Mill-Turn Centres

- Capacity; up to 3000 x 1250, turn up to Ø1600

1 off 5-Axis Turning Centre with robot loading

- Up to diameter 300 capacity

10 off CNC Machining Centres

- Up to 3000 x 1250 capacity

9 off CNC Lathes

- Up to diameter 1650 capacity

1 off EDM Sparking centres

- Up to 850 x 520 capacity

1 off EDM Wiring centre

- Up to 700 x 500 capacity

3 off Surface Grinders

- Up to 2000 x 1000 capacity

5 off Universal Grinders

- Up to diameter 300 x 600 capacity

Inspection Centres

- Including CMM & Projectors

CAD/CAM

Every CNC machine is complimented with an AlphaCAM worksation, & these are supported by our in-house design team, utilizing these software suites;

- Autodesk PowerMill 2025

- Autodesk PowerShape 2025

- Autodesk Inventor 2020 (4 workstations)

- Autodesk Autocad 2020 (4 workstations)

- ECS Concerto (4 workstations)

Investment in People

Without the appropriate personnel , any business will suffer. Burnsall Engineering strives to employ only the highest skilled workforce to run in parallel with the state-of-the-art machinery we employ. A stringent screening & interview policy ensures only the highest level candidates with many years of relevant experience are selected to create the moulds & machined components you require.

We also offer apprenticeships to some of the most promising young engineers from local technical colleges.

Investing in people with regular training in all aspects of our engineering techniques is what keeps us at the front of the industry, giving you the results you require.

|